Mohammed Abdul Haleem will be our expert technical writer in a series of articles to be presented in successive PRESSIdeas issues. Here is the 4th one discussing flexography as a high-quality, economical alternative to gravure and offset lithographic printing.

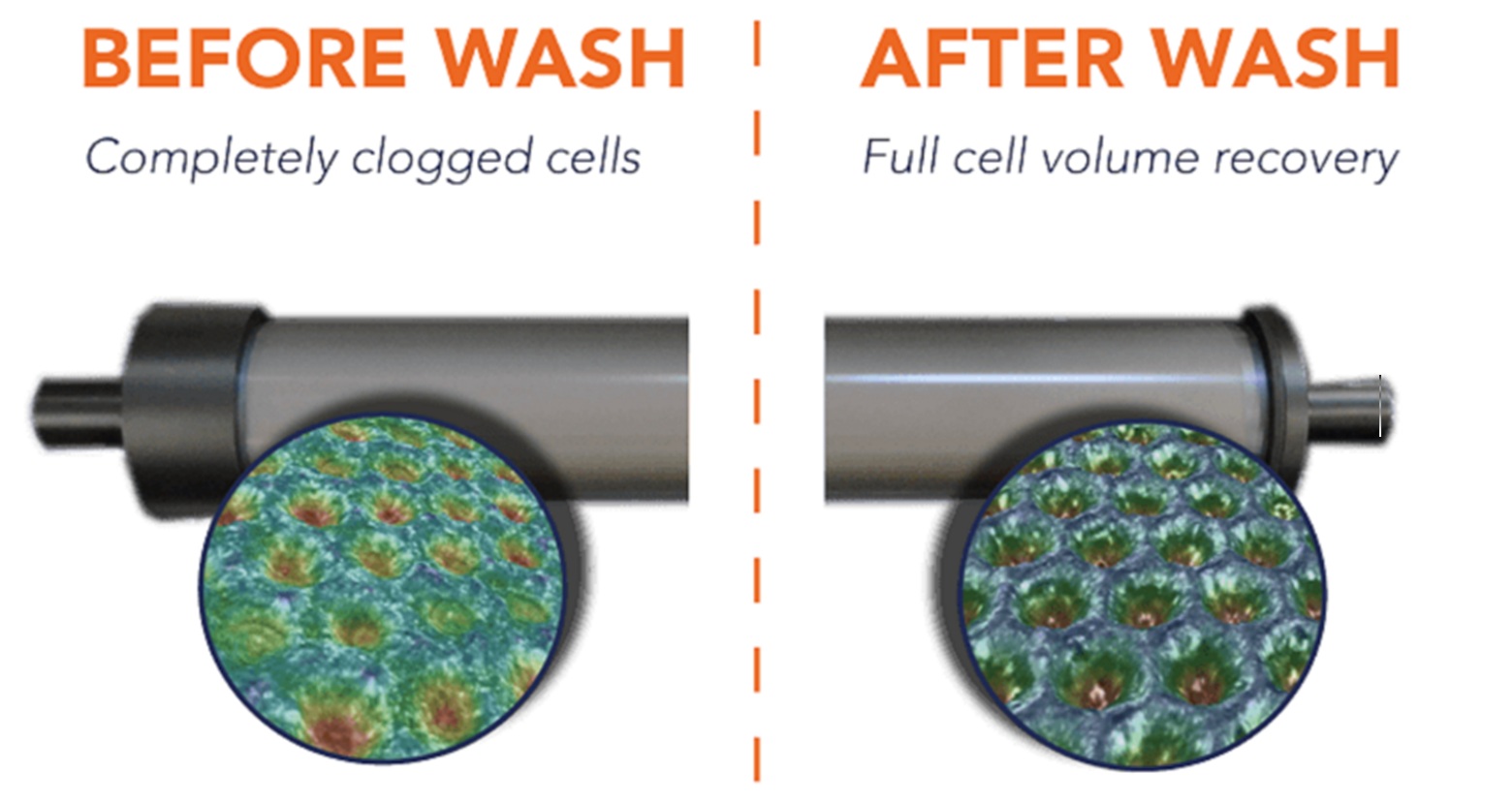

Proper care of the anilox roll – a critical flexo tool – can be achieved by one of several available methods. One type of roller among the many that inhabit a flexographic printing press receives the most attention, and with good reasons. The anilox roll has been described as the heart of the flexo press, and as such is deserving of proper attention and care. Its surface is composed of millions of invisible cells that capture and transfer ink, and must continue to do so hour after hour at constant speed without failing.

Introduction

Introduction

While there are a number of variables that can contribute to poor printing, a dirty, plugged anilox will always result in major print quality problems, which result in production waste.

A dirty roll will have reduced ink carrying capacity, causing coverage and colour density problems. Regardless of the cleaning method used, it is important to thoroughly clean rolls as soon as possible after the pressrun. By their nature, water inks, unlike solvent inks, do not readily re-wet. Once dried cleaning is difficult, the dried ink is very abrasive and can cause damage to the ceramic or chrome coating on the anilox rolls.

If the ink is allowed to dry on the surface of the anilox roll, it will require more aggressive solvent or caustic cleaners to adequately remove the ink from the cells. Fine screen count anilox rolls are, by the nature of the much smaller cells, more susceptible to quicker plugging. They will require more frequent maintenance and are more difficult to clean.

Anilox roller cleaning – physical

Exactly how it works:

There are usually two types of chemical anilox roller cleaning:

- Daily cleaning after each new set-up and deep, acid-based cleaning every 1-3 months. Daily, anilox rollers are washed with link-specific solvents after each retooling.

- Every 1-3 months aggressive chemicals are used for deep cleaning with a decent steel brush applying the agent on the roller and letting it react, penetrate the ceramic surface and clean.

Advantages: No tools necessary. Quick cleaning process.

Disadvantages: The use of chemicals on some anilox rollers containing light metal or rubber elements and bodies can lead to surface damage. The process is manual and so not fully repeatable and precise. Manual washing with chemical agents may have a negative impact on operator health, the environment and chemical waste generation that needs to be neutralized.

Precautions: Operators must use proper safety clothes and equipment (goggles and protective gloves).

Day-to-day cleaning:

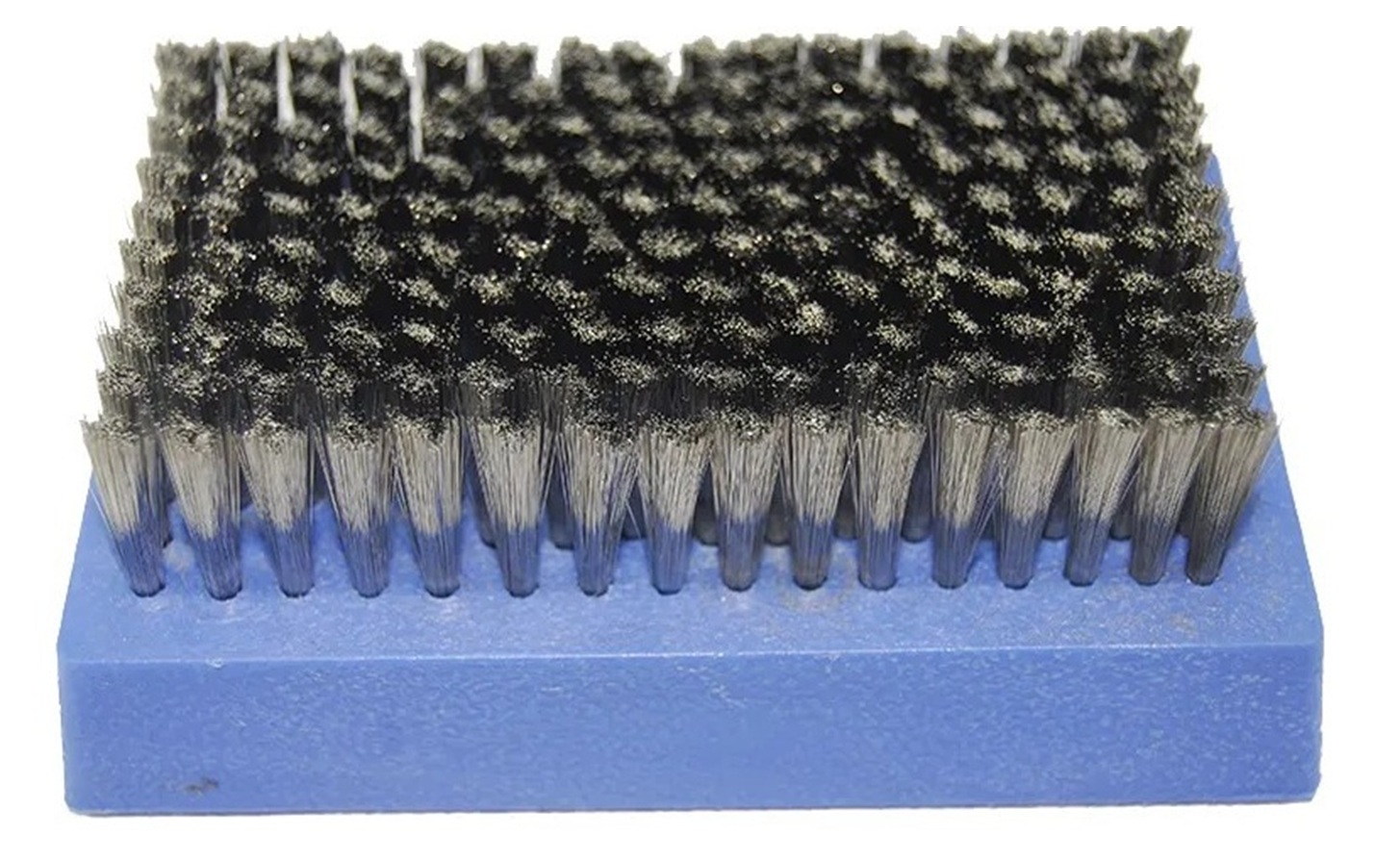

Daily on-press cleaning will help maintain printability. At a minimum, after each run, circulate solvent or water through the inking system using the ink pumps while rolls are turning. Then the roll should be scoured.

- On chrome coated rolls a brass bristle brush should be used.

- A stainless bristle brush should be used on ceramic coated rolls.

A good, daily hard scrubbing will go a long-way toward maintaining “open cells” on your rolls.

A good, daily hard scrubbing will go a long-way toward maintaining “open cells” on your rolls.

There are also mechanical systems that may be used on-press to clean anilox rolls:

Blast systems utilize a pressurized cleaning head with vacuum removal as the cleaning system. The cleaning head is moved, by hand, across the roll. These systems utilize compressed carbon dioxide, fine particle materials such as baking soda, or plastic beads to remove dirt and ink.

Chamber doctor blade units, with internal nozzles connected to a pumping system, flush the anilox cells cleaning solution which may consist of water, surfactant solution, solvent, or a caustic solution.

Flushing systems use pumps to flood the inking system with clean-up solution.

For maximum maintenance of anilox cell volume, rolls should receive a thorough cleaning as-soon-as they are removed from the press. This can consist of hand cleaning with a brush as described above, or placing the roll in a machine specially designed for roll cleaning. There are several technologies used to deep clean anilox rolls, including ultrasonic, pressure, media and laser cleaning.

Ultrasonic Cleaning

Ultrasonic cleaning consists of a tank of cleaning solution (commonly a detergent or caustic bath). High efficiency cleaning occurs because sound waves, created by ultrasonic transducers, create microscopic bubbles that collapse or “implode” producing shock waves. In anilox cleaning these microscopic bubbles implode in the cells and force the ink out.

The process consists of placing them into a heated tank containing the cleaning solution and is slowly rotated. This exposes all surfaces of the roll to the action created by ultrasonic transducers in the bottom of the tank. The combination of heat, chemicals and the imploding bubbles, effectively lift the dried ink off the roll.

Advantages:

Ultrasonic cleaning is very effective with all types of ink used in flexography. It is also easy to install and operate.

The process is fully automated. It is easy to filter the cleaning agent so it can be reused for an extended period of time, which is very economical. The system has low water consumption.

Investment costs are relatively low and the washing machines can be easily adapted to suit the individual needs of the printing company.

Ultrasonic washer specification contains the number of units in the machine, working unit length and internal and external diameter. The machine can be fitted with single or double frequency and rinsing functions.

Disadvantages:

Be aware that excessive exposure time can cause cell damage.

The roller must cool down to room temperature before re-installation.

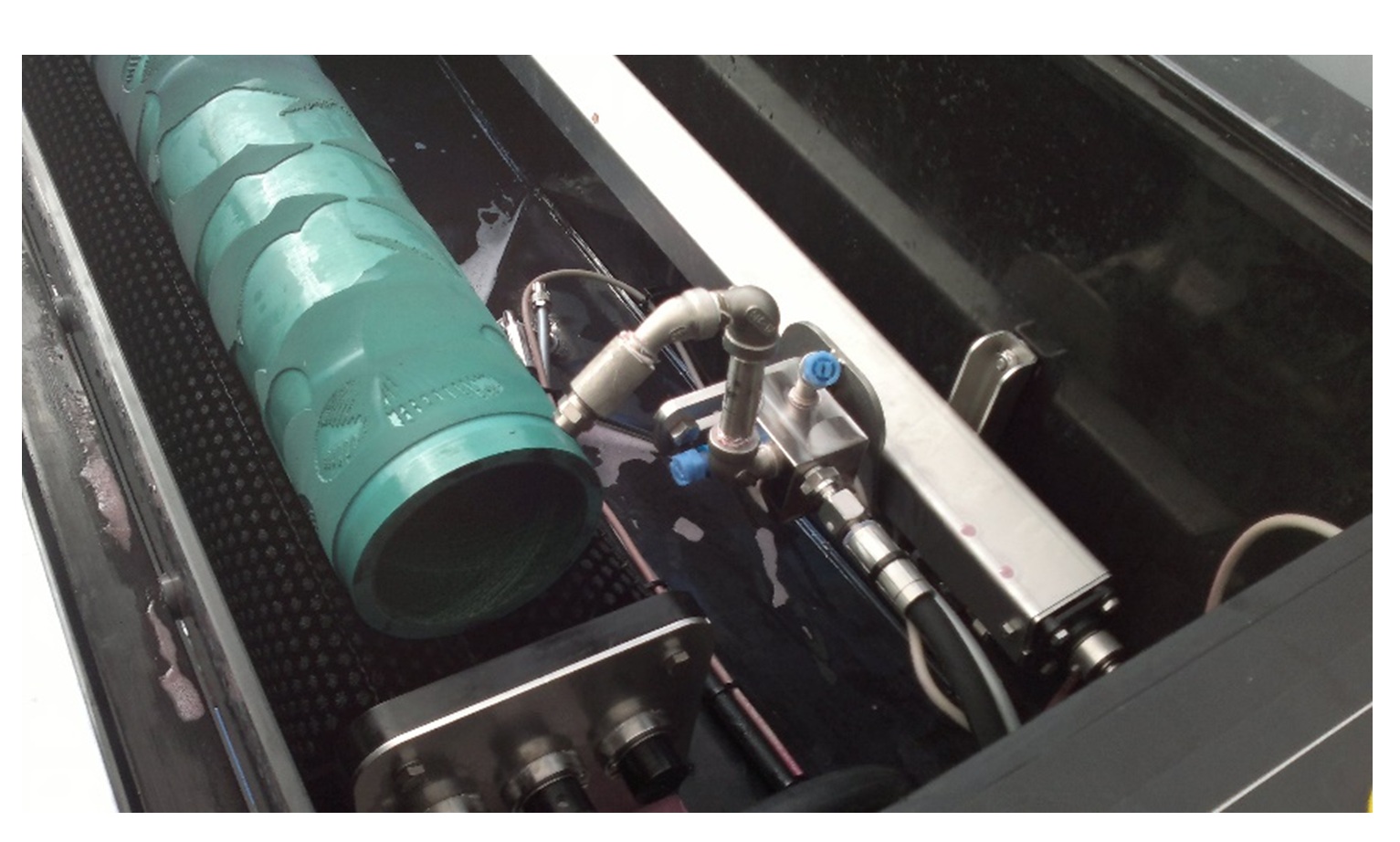

Pressure Liquid Anilox Cleaning:

There are two types of pressure cleaning: spraying a high pressure liquid directly on a roll, and soak-pressure wash immersion systems.

Usually it is based on liquid and high-pressure water. Therefore the system is effective even for high line aniloxes. The quick and gentle cleaning process leaves the rolls totally clean and ready for immediate use after just 10-20 minutes cleaning without causing any wear or tear to the roll.

This makes it possible to keep your anilox rolls totally clean at all times ensuring a high and consistent print quality and a long lifetime of the anilox rolls. Cleaning is usually done in an enclosed glove-box cabinet using a heated caustic or detergent cleaning solution. A solvent would not likely be used due to the risk of fire/explosion.

A soak-pressure wash immersion system consists of a tank to hold the bath, heaters, a rotating roll-holder, pumps and filters. The pump supplies the heated liquid under pressure through the bath (spray under immersion) and into the anilox cells.

Laser anilox cleaning system:

Laser anilox cleaning system:

The anilox roller absorbs the energy of the laser beam, which has a high-intensity impact on its ceramic surface. It leads to the so-called cold evaporation of all types of contamination from the roller. A suction unit for removing ink resides and other contaminations are required. The process takes about 45 minutes to complete.

How Laser Cleaning Works

Laser cleaning technology works by sending nanosecond-length pulses of laser light towards a surface. When it interacts with contaminants that absorb laser light, the contaminants or coating particles will either turn into a gas or the pressure of the interaction will cause particles to free from the surface.

In addition to its cleaning capabilities, laser technology has added benefits:

It is easy to operate, safe, easily automated, quiet, and reliable. It doesn’t require cleanup, comes with low operating costs, it’s low maintenance, and environmentally friendly.

Conclusion:

The decision to choose an anilox cleaning technology needs to be taken concerning the needs of a particular production process. The key element should be an honest analysis of the advantages and disadvantages of particular cleaning methods relative to the production profile and inventory of anilox rollers. One must take into account the speed, efficiency, investment costs, and environmental impact. Before investing it is important to be able to test the method under production conditions, verify its impact on the condition and wear of anilox as well as check the efficiency of a chosen cleaning method through volumetric measurement (cm3/m2 / BCM) after washing anilox with different screen rulings.

Mohammed Abdul Haleem, with 30 years of experience in the Printing Industry, offers professional guidance on a wide range of technical topics related to Flexographic Printing, CI, Stack, Narrow web, offset, flexography, rotogravure, letter-press, screen printing and digital printing technologies and other areas like, support for product management, sales & marketing methods and business building responsibility in areas of the above mentioned fields.